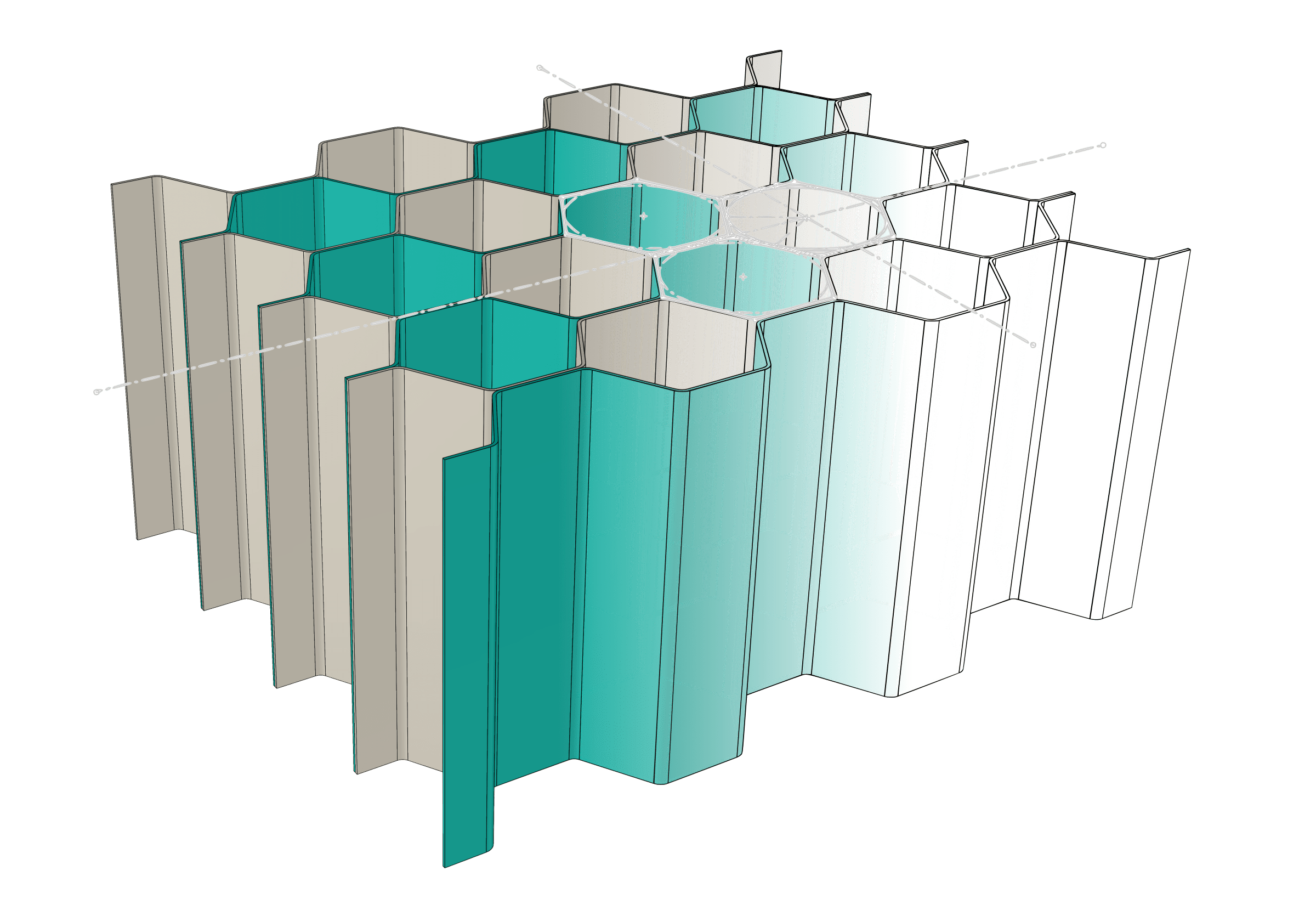

The novelty of the approach employed lies in basing structural optimization on the topologies and architectures of the core materials. Structuring the geometries, rather than using higher-performing constituent materials (which in most cases leads to increased manufacturing costs due to higher raw material prices),

allows for adapting performance to desired objectives: equivalent performance with less material, resulting in reduced production costs and a lighter weight, or increased and improved performance with equivalent material quantities, or even finding a balance between these two extremes.

Design and modeling are at the heart of EC3D's approach.

Our design tools are directly linked to our internal machine park (3D printer, CNC machining).

Research and development, design and modeling, performance analysis – we put our expertise at the service of your project.