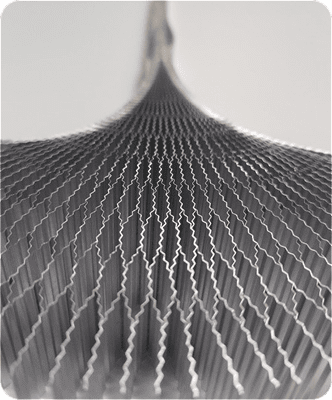

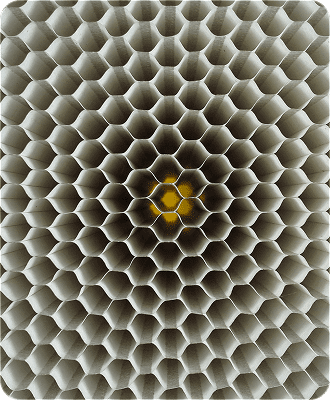

Designing and modeling new ultralight structures would be pointless without the ability to evaluate them concretely, both in terms of specific implementation and expected properties.

We develop all the necessary tooling for our concepts in-house, from design to manufacturing.

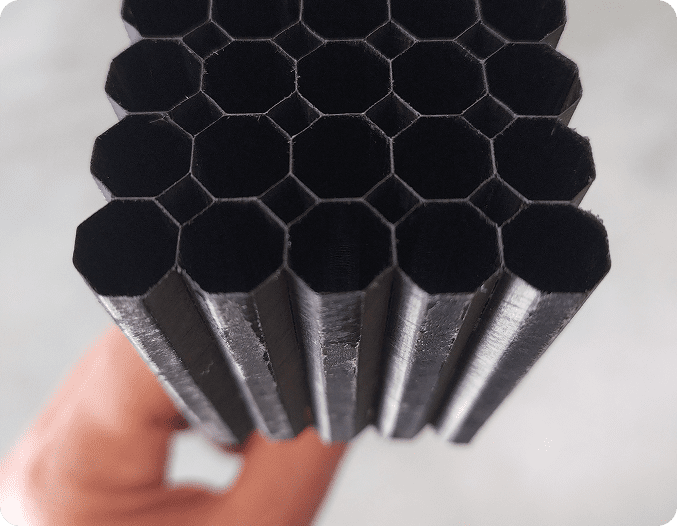

We implement and shape the identified and selected base materials for validation according to defined protocols.

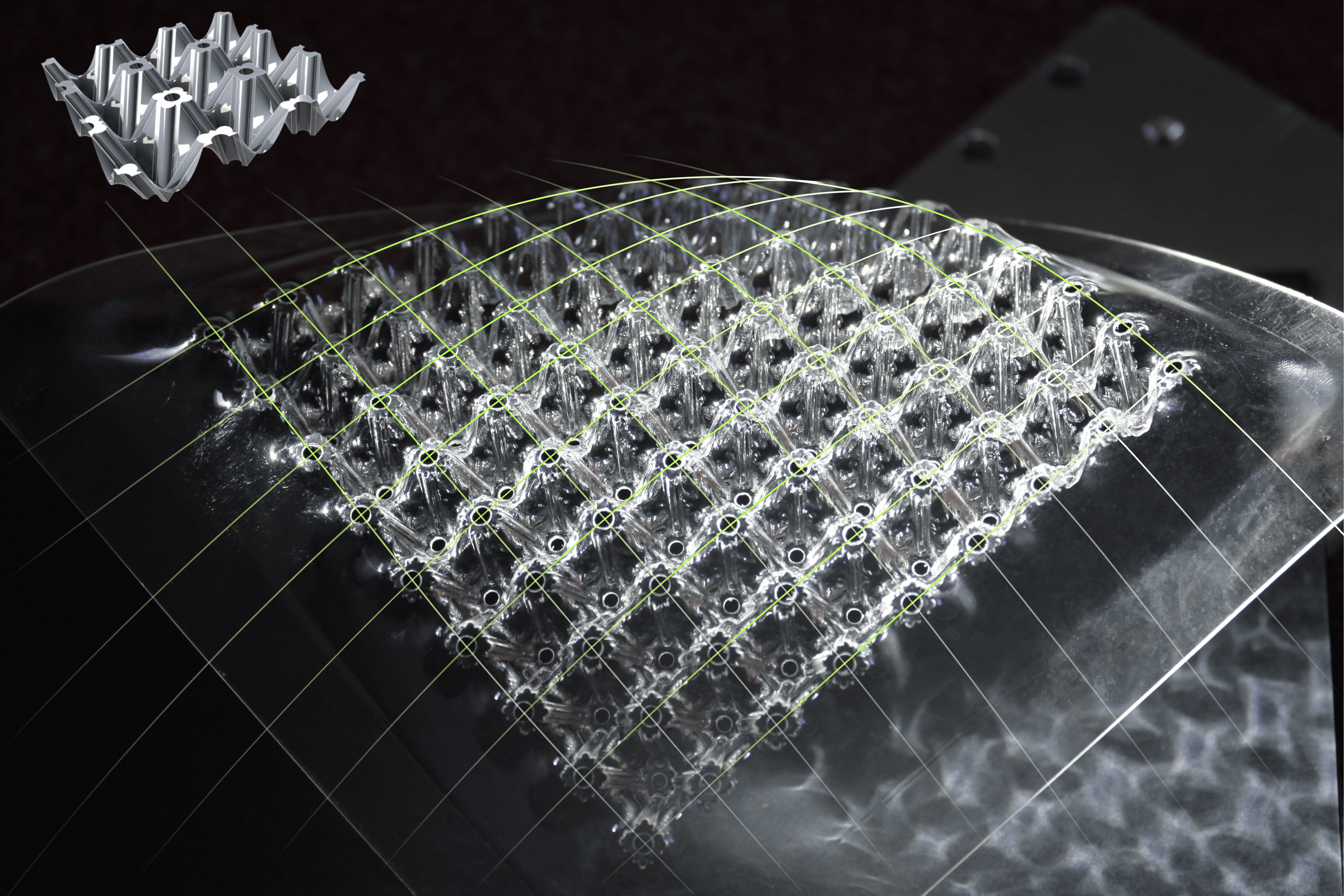

Creation of the first models based on a defined set of specifications.

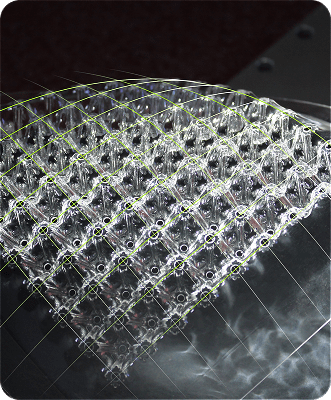

In-house manufacturing of molds and necessary tooling.

Implementation of raw materials (prepreg draping, thermoforming…)

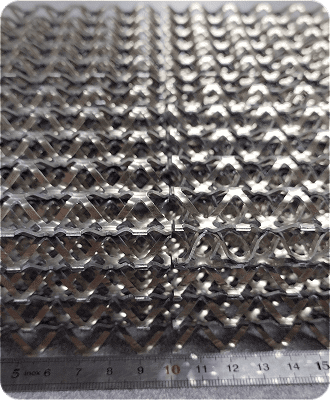

The prototypes are analyzed and submitted for validation if they meet the initial objectives.

If necessary, improvements and optimizations are made to meet the specifications set.

From design to the realization of innovative structures, EC3D masters all the stages for greater confidentiality.

From machining to the implementation of materials and associated techniques such as:

Implementation and prototyping are at the heart of our approach.

Research and development, design and modeling, performance analysis – we put our expertise at the service of your project.