Out of plane elastic compressive properties of metallic honeycomb structures

By Frédéric Brun

Influence of the stabilization process on the mechanical properties of a honeycomb_Aux_Défense_2020

application/pdf – 1.6 MB

DownloadThe influence of the stabilization process on the mechanical properties of a honeycomb structure is analyzed to improve explosion protection.

The context and objectives are :

The study on physical protection against explosive charges, the improvement of knowledge on sandwich cladding, with the objective of reducing the transmitted charge impulse and improving the database of absorbers.

Materials and experimental setup :

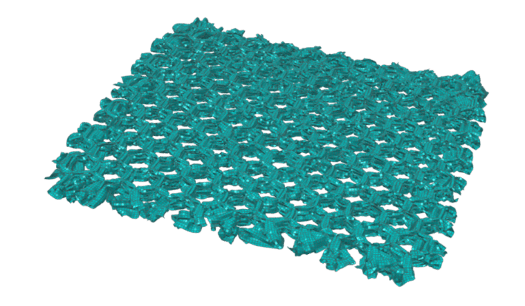

Metallic honeycomb with varying dimensions (75×75 mm, height from 20 to 100 mm).

Stabilized with aluminum foil and epoxy adhesive.

Quasi-static tests performed with an INSTRON machine.

Experimental and numerical results :

Low dispersion of results (< 5%) for plasticity stress.

Successful numerical modeling for the honeycomb in stabilized and unstabilized configurations.

Comparison of compression behavior between the two honeycomb types.

Analysis of material parameters :

Influence of the stabilization process: increased plateau stress and plasticity, but reduced densification strain.

The honeycomb height influences densification strain and toughness.

Conclusion :

Further tests to measure the compression modulus are needed.

Future work will investigate the influence of honeycomb structure topology.

Dynamic tests, driven by explosives, are planned using a shock tube device.

Influence of the stabilization process on the mechanical properties of a honeycomb_Aux_Défense_2020

application/pdf – 1.6 MB

Download