Influence of the stabilization process on the mechanical properties of a honeycomb_Aux_Défense_2020

By Frédéric Brun

OUT OF PLANE ELASTIC COMPRESSIVE PROPERTIES OF METALLIC HONEYCOMB STRUCTURES

application/pdf – 12.04 MB

DownloadThis research evaluates the influence of three geometric factors on the out-of-plane compression modulus of metallic honeycomb structures, specifically aluminum: cell topology, honeycomb structure height, and sample geometry. The objective is to verify whether the typical modulus values provided by manufacturers, often assumed to be constant, remain valid under different configurations.

Historically, theoretical models (notably those of Gibson & Ashby) have proposed a formula linking this modulus to the relative density and Young's modulus of the material. However, significant discrepancies are observed between theoretical and experimental moduli, especially for low-density honeycombs. This is explained by micro-defects such as micro-perforations and micro-buckling of the walls, as well as by the overestimation of Young's moduli for very thin materials.

To investigate these phenomena, compression tests according to ASTM C365 were carried out, as well as finite element modeling (FEM). The tests show that cell topology strongly influences mechanical performance: a modified geometry with corrugated walls significantly increases the compression modulus (up to +118% for only a 7.9% increase in density) compared to a classic hexagonal structure.

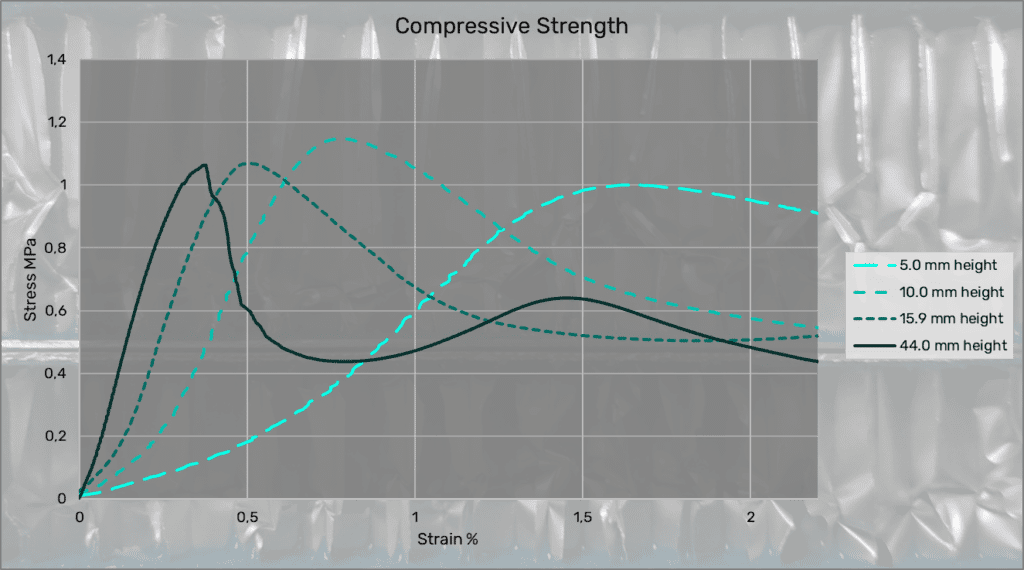

Furthermore, the honeycomb height (a parameter absent from the theoretical formulas) also has a significant impact. Tests on heights of 5 mm, 10 mm, 15.9 mm, and 44 mm reveal that the compression modulus increases with height, also reducing the elastic deformation zone. For lower heights, the adhesive used in the stabilized compression tests appears to influence the results.

Numerical simulations accurately reproduce these experimental trends, highlighting two elastic regimes: a first theoretical regime followed by a second regime dominated by micro-buckling. This numerical approach confirms that mechanical performance depends not only on the material and density, but also on the cell geometry and the core material height.

In conclusion, this study demonstrates that the out-of-plane compression modulus of metallic honeycombs is not a universal constant. It depends strongly on the geometric characteristics of the cellular network, which challenges the simplifying generalizations often used. Integrating these factors is essential for applications requiring high mechanical precision, particularly in the aerospace industry.

OUT OF PLANE ELASTIC COMPRESSIVE PROPERTIES OF METALLIC HONEYCOMB STRUCTURES

application/pdf – 12.04 MB

Download